FAQ

The main difference lies in the type of tool and in the quality of bevel finishing.

The nibbler/shearing machine mounts a multi-cutting cutter with fixed teeth, which must be re-sharpened by specialized personnel when worn. This can be repeated a few times, after which the cutter needs to be replaced.

During its work of “material tearing”, the cutter also acts as an advancement of the sheet to be bevelled or of the entire machine. This dual function makes it subject to breakage.

There are no cutters suitable for each type of material, but only more or less hard cutters. Multi-cutting cutters do not lend themselves to machining alloys, alloy and stainless steels. The finish they allow to obtain is that of a torn material, which needs further processing.

The bevelling machine mounts a cutter with interchangeable inserts, which vary by type (inserts are available for all types of materials) and brand. Only the insert wears and, after using it on all its multiple cutting sides, it must be replaced.

The finish is the Best that can be obtained among all existing bevelling solutions!

Cutter with reduced number of inserts:

- Lower cost of replacement

- Equal number of bevelled meters

- Greater stability with less vibrations

- Less overheating of the material

- Better performance on hard materials

- Cost of the chamfer per linear meter very low

- Possibility to perform both large and small bevels in a single pass, with high feed speed

- total innovation in the preparation of bevels for welding

- possibility of creating medium / large bevels

- top bevel quality

- constant size of the bevel

- speed of processing

- easy to use

- complete elimination of the grinding phase

- RIGIDITY DURING PROCESSING

- STABILITY OF THE MACHINE ON METAL SHEET

- FEEDING SPEED ALSO WITH LARGE

DEPTH OF CUT - NO VIBRATIONS

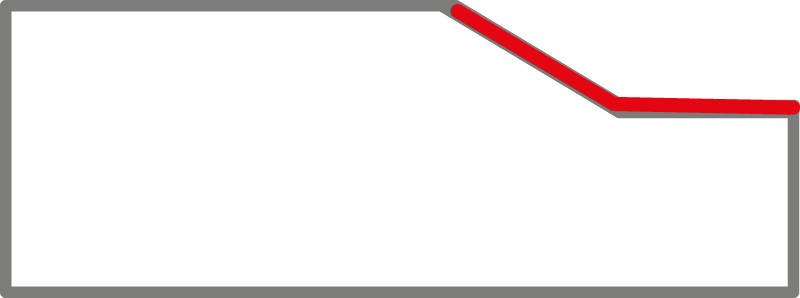

- often, already on thicknesses over 20 mm, the “J” bevel replaces the “V” and “K” bevels

- huge saving of the welding material, as it brings less material

- huge savings of the welding time, since it is possible to weld automatically, from the first pass

- less thermal stress on the material

By “Clad” we mean the removal of the plated material on bimetal plates.

Certain applications, such as the production of pressure vessels used in the petrochemical and pharmaceutical sector (silos, heat exchangers, etc …) require the use of sheets with a surface coating with different material.

Welding requires the removal of the material used for the coating because a weld on two different materials is not possible.

The advantages:

- Double productivity

- Less time in which the plates remain still for bevel

- Same operator who manages two machines simultaneously

- Halved Cost per linear meter

- Greater flexibility

- Machine downtime reduced by 100%

- Purchase costs do not double compared to a single machine

The bevelling operation at professional levels requires targeted solutions, reliable and performing, practical, fast and safe.

The multifunction machines are a compromise of the various solutions, aimed at hobby use.

In professional use they are not performing in any solution!

OMCA uses commercial inserts produced by the main world manufacturers, giving FREEDOM to anyone to find the spare part on their territory.

The life of the insert is conditioned by multiple factors, sometimes empirical, such as the type and quality of the material, the way the material is cut and the hardness that derives from the cut itself (for example, laser cutting is the one that gives the greatest hardness to the material, followed by plasma and oxyfuel cut) the origin of the sheet and the dimensions of the bevel (the more passes are carried out to obtain the final dimension of the bevel, the more inserts are required).

Using specific, professional, powerful and performing bevelling machines, which do not generate vibrations and allow to perform bevels in fewer steps.

If you are not equipped with bevelling machines you must resort to outsourcing and this entails a higher cost of the bevel per linear meter.

OMCA has adopted four feed wheels on some machine models, in order to be able to perform bevels with significant depth and with high feed speed, reducing bevelling times by 30%.

The OMCA bevelling machines, once clamped on the sheet, are the ONLY of their kind, which can work in SUSPENSION, that is, without the wheels touching the ground / floor!

Depending on the thicknesses, the type of material, the size of the piece, the angle and the type of bevel.

Thanks to the use of milling cutter with inserts, because with the choice of the correct insert you can bevel any type of material from light alloys to harder materials such as weldox, armor and hardox.

OMCA has the widest range of bevelling machines on the market from those in the bench version, to the portable and automatic ones, therefore, depending on the size of the piece, it finds a solution.

If a solution is not found in the standard range, OMCA is able to offer a tailor-made solution.